DEDICATED OUTDOOR AIR SYSTEMS

The most common drivers for choosing a dedicated outdoor air system (DOAS) are to:

- Improve IAQ through proper ventilation to all spaces

- Meet ventilation code requirements

- Improve humidity control

- Reduce energy use

- Enable use of heating/cooling equipment that does not provide ventilation and/or dehumidification, such as radiant panels, chilled beams, or VRF

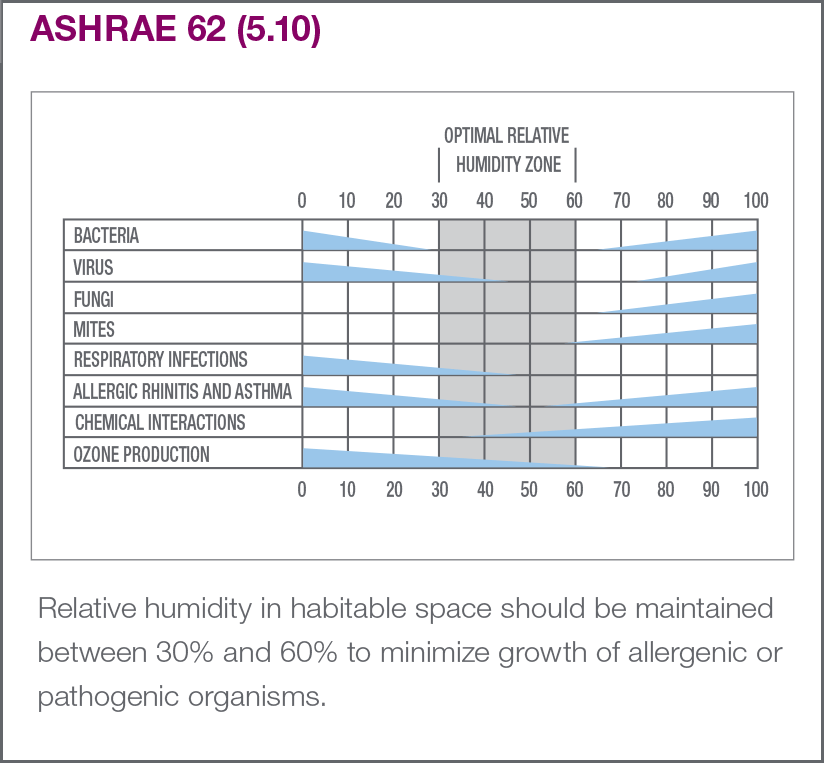

Incoming ventilation air typically carries more than 80% of a building’s annual dehumidification load. Most traditional air handling units cannot handle such high latent loads over a wide range of ambient conditions. DOAS equipment is designed to handle high latent loads.

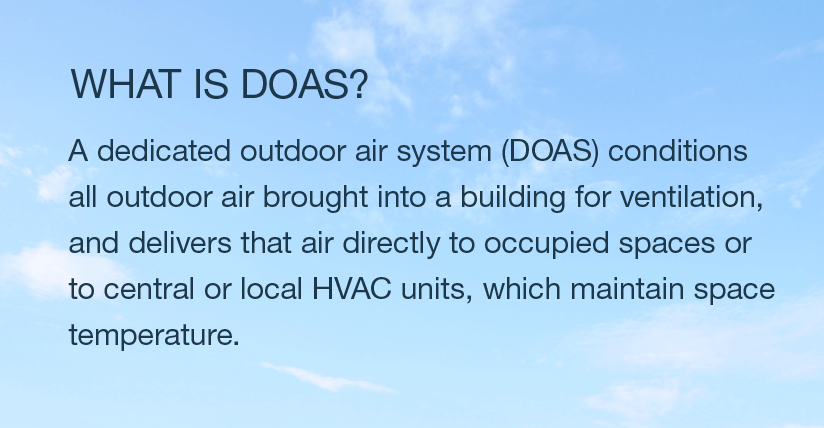

DEHUMIDIFICATION DESIGN DAY BEST FOR SIZING DOAS

When designing a high outdoor air system, both design cooling conditions and design dehumidification conditions must be considered. However, designing just for temperature can result in not meeting desired space conditions and can lead to mold, structural degradation, and poor indoor air quality caused by excessive moisture in the space. Consider the following example:

- Location: Oklahoma City, OK

- Application: 100% outdoor air

- Desired space set point: 75 °F

- Desired space humidity: 50% RH

Equipment designed using cooling design day (99 °F DB/74 °F WB)

If only design cooling conditions are considered, the DOAS equipment will not be able to maintain the desired space humidity set point when outdoor dew points are at or above 63 °F.

Equipment designed using dehumidification design day (84 °F DB/77 °F WB)

Conversely, if dehumidification design conditions are used, the equipment will meet desired conditions for both temperature and humidity at outdoor dew points up to 74.5 °F.

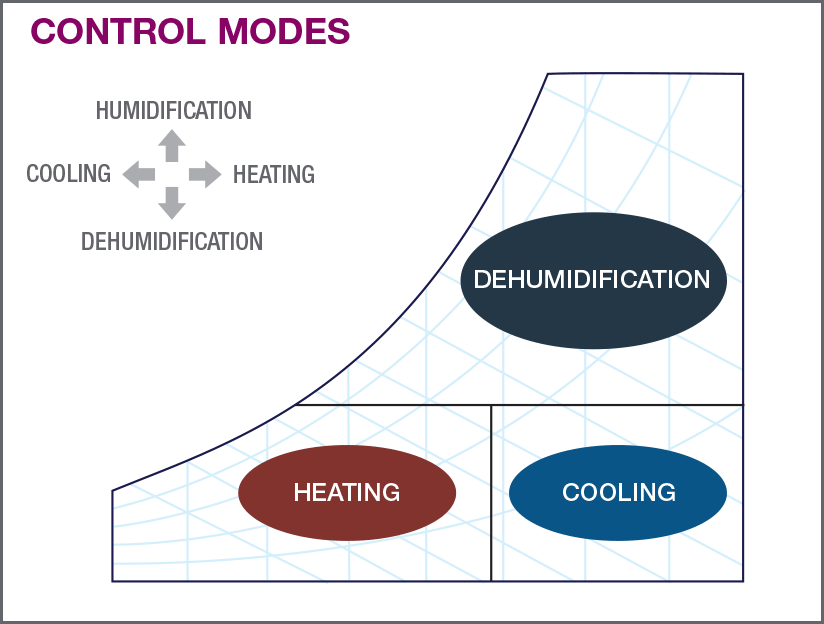

DEDICATED CONTROL MODE ENSURES RESPONSIVE RH

Keeping space conditions cool and dry is far easier than trying to regain control of an overly humid space when introducing high amounts of outdoor air. Systems that simply control the leaving air temperature, or use cooling mode to dry the air, cannot meet or maintain desired space temperature and relative humidity.

Ensuring proper humidity levels requires a separate dehumidification mode that measures and controls to the actual dew point off the coil.

A dedicated dehumidification control mode recognizes when humidity conditions are changing and moves the control point to a dew point sensor measurement off the coil. Cool, dry air is then reheated using the free energy of hot gas reheat.

Dehumidification mode can be activated based on outdoor conditions or space/return air conditions. Choosing the condition that triggers a control change to dehumidification mode depends on the application. As indicated below, applications bringing in large amounts of outdoor air generally activate dehumidification based on outdoor conditions to avoid falling behind in managing space humidity.

Triggering Dehumidification Mode

Dehumidification Mode can be triggered by outdoor or indoor conditions.

- Choose Outdoor Conditions if the unit is designed to provide:

- High percent of outdoor air

- High number of air changes

- Precise control of the space

Choose Space/Return Air Conditions if the unit is designed for:

- High amounts of re-circulated air

- High internal loads

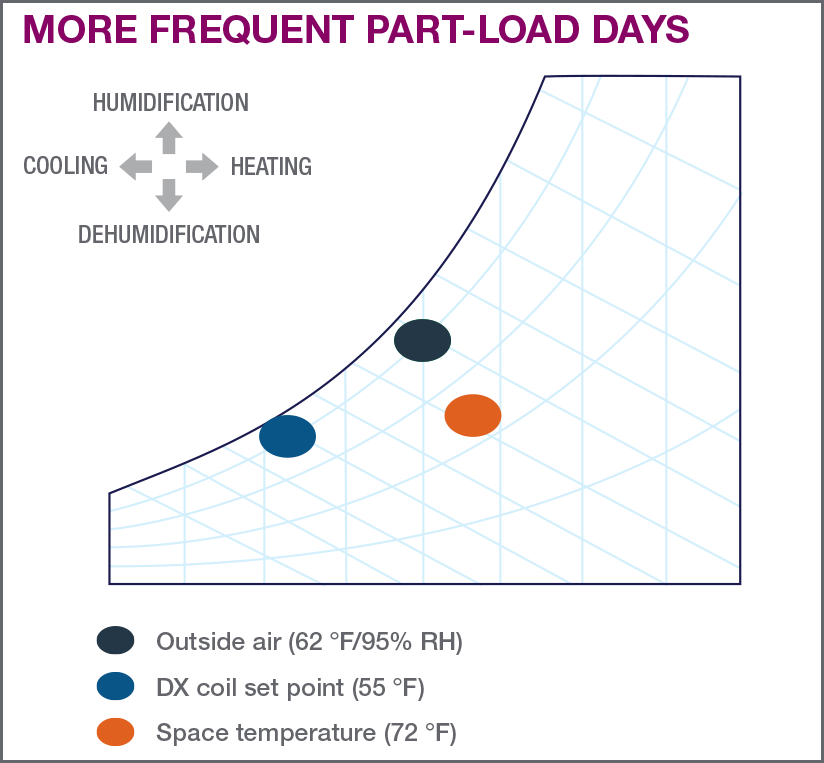

DEHUMIDIFICATION MODE BEST FOR PART-LOAD DAYS

While design days create challenges for both temperature and humidity control, the more frequent part-load days present a different challenge. For example, cool, dewy summer mornings require dehumidification to dry out the incoming air but the resulting dry, but too cool, air will result in spaces that are too cold for occupants. Instead, dehumidify to the right dew point and then use reheat to deliver comfortable temperature and humidity levels to the space.

OPTIONS FOR PART-LOAD OPERATION

- Economizer mode

- Unacceptable space humidity

-

Cooling mode

- Over-cooled space

-

Dehumidification mode

- Dries air to the proper humidity level

- Uses reheat to maintain proper space temp (with hot gas reheat and/or downstream duct heater)

WANT TO LEARN MORE?